Background reading:

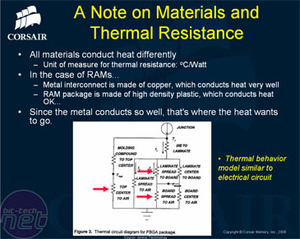

As memory gets faster, heat becomes more of an issue because DRAM transistors generate heat when they switch: the faster they switch, the more heat is produced. Typically, Corsair's XMS memory modules are clocked at higher frequencies and voltages than they were designed for, meaning that there is an immediate need for cooling. Heat becomes an issue because as transistors get warmer, they get slower, meaning that performance can be sometimes less-than-optimal if you've pushed a memory module too far with improper cooling.While heatspreaders don't do much for memory at low speed, when modules start operating at higher frequencies, the heatspreader helps to reduce DRAM temperatures by spreading the heat out over a larger surface area. On the other hand, heatsinks are designed to draw heat out of the components they're cooling and transfer it into the surrounding air. In order to explain some of Corsair's design choices on the Dominator modules, we need to give a short physics lesson.

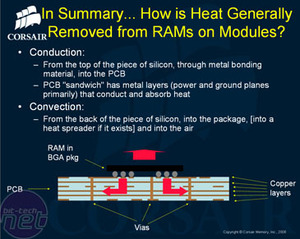

There are two ways to remove heat from a semiconductor - either via conduction or convection. Conduction is where heat is removed from the semiconductor using a stationary conductive material (such as aluminium), while convection is the process where heat is radiated from the semiconductor into a gas or liquid.

Dual-path Heat Xchange Cooling:

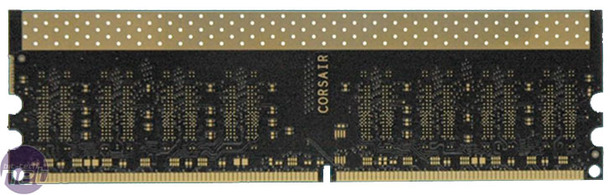

Because the Dominator modules - especially the Twin2X2048-8888C4DF part - are run massively out of specification, Corsair needed to address the potential heat problems that it could encounter by designing a completely new cooling solution. You've already seen the heatsink design on the previous page, but there is more to the Dominator heatsink than meets the eye at a glance. Lets start by having a closer look at the heatsink design.

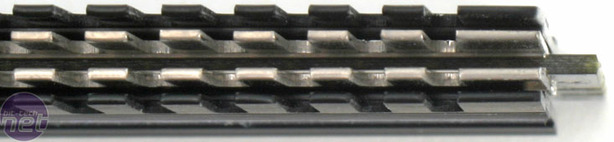

top of module (cropped)

There are a total of four heatsinks for each memory module: one cooling the PCB and one cooling the DRAM chips on either side of the module. The outer heatsink makes use of fins that are designed to help to maximise convection regardless of the direction of airflow. They're built from extruded aluminium using a process specifically designed for optimal heat removal and are anodized black. The outer heatsinks are directly attached to the DRAM chips and are not directly connected to the PCB.

Image courtesy of Corsair Memory

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.